The Canadian Printing Industries Association (CPIA) hosted an outstanding webinar on October 15 — Finishing Game Changers: Maximizing Productivity in Post-Press — bringing together industry experts to discuss the technologies and strategies shaping the next generation of automation in print finishing. Connecting for Results was pleased to participate, share data-driven insights, and contribute to an engaging conversation about where the industry is heading.

A sincere thank-you to the CPIA team for organizing such a valuable session and to all the speakers who shared their expertise: Bob Dale (Connecting for Results), Carlos Martins (Mueller Martini), Patrick Douglas-Meis (PDM International), Scott Cherewayko (Friesens Corporation), Greg Best (Deschamps Printing), and Ian Heslin (Seaway Printing).

1. Productivity Challenges in Canadian Manufacturing

Bob Dale opened with an honest look at the productivity gap facing Canadian manufacturers. Smaller operations, limited investment, and ongoing labour shortages underline the need for automation in print finishing and smarter workflows across production environments.

Drawing on national data, Bob highlighted that Canadian firms invest roughly one-third as much per worker in technology as their U.S. counterparts, or $4,100 versus $12,000 annually. He emphasized that this underinvestment, combined with labour constraints, limits output per hour worked and reinforces the urgency of digital transformation in finishing operations.

2. Technology Investment Gap

Referencing recent CPIA–CFR survey data, Bob highlighted that finishing equipment investments remain the lowest among all capital categories. This is a missed opportunity, considering that finishing determines both turnaround speed and profitability.

He explained that while many companies paused capital expenditures amid economic uncertainty and postal disruptions, the tide is turning. New research from Keypoint Intelligence shows a growing appetite for robotics and workflow software, signaling that printers are ready to close the investment gap and modernize their finishing departments.

3. Growth of Robotics and Automation

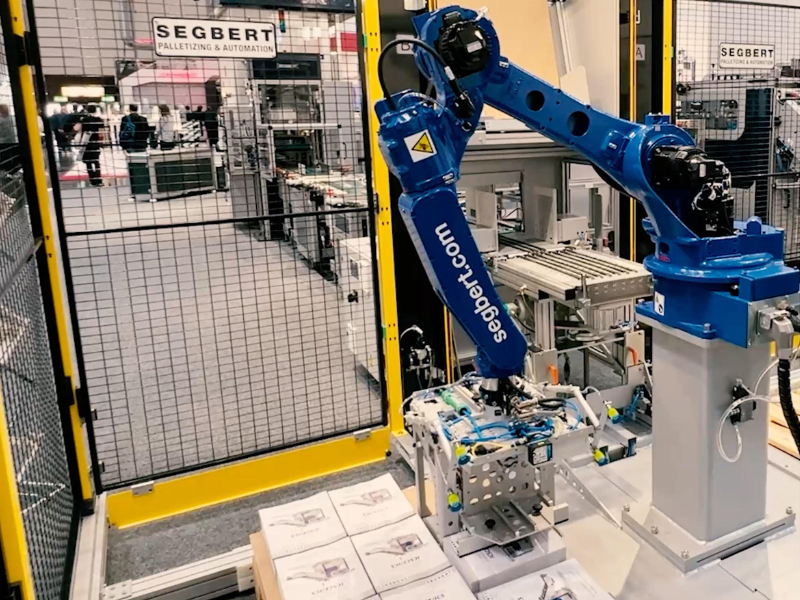

Bob and Patrick Douglas-Meis explored how robotics, from palletizing to cobots, are addressing persistent labour shortages and improving output consistency. The technology is no longer futuristic. It’s fast becoming essential for automation in print finishing.

Patrick illustrated this point with real-world examples from European and North American print plants using collaborative robots that can be repositioned in minutes. These mobile cobots simplify end-of-line automation and reduce the footprint of traditional robotic systems, offering printers flexible, lower-cost entry into automation.

4. Four Core Pillars of Modern Finishing

Carlos Martins outlined Mueller Martini’s focus on automation, connectivity, variability, and touchless workflow. Together, these are the foundation for modern, adaptive finishing operations ready for shorter runs and complex personalization.

He described how these four pillars emerged from years of innovation, beginning with Drupa 2016. Each new system design now seeks to minimize human intervention, synchronize machine data, and manage variable product formats. The result is increased speed, better accuracy, and improved flexibility in a competitive market.

5. Integration and Connectivity Across Systems

Carlos emphasized that integration between MIS and production systems is the key to eliminating manual handling and human error. Connected workflows, supported by platforms like Muller Martini Connex, create visibility and control across every stage of production.

In his presentation, he explained that real-time JDF and Connex line control enable data to flow seamlessly from prepress to finishing. Automated job batching, barcode tracking, and performance reporting make it possible to know exactly what has been produced and, more importantly, what hasn’t, ensuring total process traceability.

6. Minimizing labour through Smart Automation

Both Carlos and Patrick demonstrated how smart automation can reduce operator counts while maintaining throughput. Cobots, stream-feeding, and inline handling all play a role in optimizing labour use without compromising quality.

Carlos explained that recent advances now allow trimming, folding, and setup adjustments to be handled automatically. Patrick added that palletizing robots and signature-feeding cobots can transform previously repetitive, labour-intensive tasks into seamless, operator-light workflows that sustain high output even amid staff shortages.

7. Case Study: Short-Run Book Production

Carlos presented a real-world “book-of-one” case study showing how connected finishing lines can efficiently produce ultra-short runs with minimal human input — proof that automation in print finishing supports evolving customer demands.

He described a fully integrated system that unwinds preprinted rolls, binds, trims, and sorts individualized books automatically. Every title in the demonstration was unique, illustrating the capability to deliver personalized, on-demand production while maintaining precision, speed, and profitability.

8. Sustainability and Packaging Innovation

Patrick brought attention to sustainability trends, including paper banding and wrapping as alternatives to plastics. With environmental standards tightening worldwide, these solutions are becoming both practical and profitable.

He cited examples from European printers adopting paper-based solutions due to single-use plastic bans. Patrick noted that these practices are spreading quickly in North America, helping print providers meet new environmental regulations while creating a positive brand story for eco-conscious clients.

9. Collaborative Robotics and Flexibility

Patrick also underscored the accessibility of cobots for small and mid-sized printers. Their mobility and adaptability mean automation is no longer limited to large-scale operations.

He shared that compact robots can now be repositioned between production lines in minutes, configured for carton packing one day and signature feeding the next. This modularity allows printers to scale automation gradually, reducing both risk and capital expenditure.

10. ROI and Workforce Redeployment

The final panel — Scott Cherewayko, Greg Best, and Ian Heslin — shared measurable results. They reported ROI periods of 12–18 months, reduced labour costs, and redeployment of workers into higher-value roles. Automation, they agreed, improves morale as much as efficiency.

Scott described how Friesens Corporation repurposed over 30 employees after installing five collaborative robots, achieving payback in little more than a year. Greg and Ian added that automation has become a powerful tool for retention, reducing physical strain and attracting younger staff who are eager to work with advanced technology.

The Takeaway

The insights shared throughout the session confirm that automation in print finishing is transforming productivity, integration, and sustainability across the industry. As technology reshapes the print sector, success will depend on strategic investments, connected workflows, and an adaptable workforce.

Image of a Segbert GPA25 Robot by Patrick Douglas-Meis